-

Roulements à billes en céramique

-

608 incidences en céramique

-

Incidences en céramique hybrides

-

Roulements à rouleaux en céramique

-

Palier de butée en céramique

-

Incidence de glissement en céramique

-

Céramique structurelle avancée

-

Boule de nitrure de silicium

-

Boule de carbure de silicium

-

Boule en céramique de zircone

-

Roulements à billes de carbure de silicium

-

Roulement à billes de nitrure de silicium

-

Incidence en céramique de zircone

-

Étanchéité mécanique

-

Incidence de carbure de silicium

-

RobertaLeurs incidences en céramique sont de haute précision, bons qualité et peu coûteux. Nous avons la coopération depuis de nombreuses années.

RobertaLeurs incidences en céramique sont de haute précision, bons qualité et peu coûteux. Nous avons la coopération depuis de nombreuses années. -

Olga WeinbergCette société est notre fiable et le fournisseur professionnel des incidences en céramique depuis de nombreuses années, leurs incidences en céramique, qui sont utilisées dans notre pompe sont bon de la qualité.

Olga WeinbergCette société est notre fiable et le fournisseur professionnel des incidences en céramique depuis de nombreuses années, leurs incidences en céramique, qui sont utilisées dans notre pompe sont bon de la qualité.

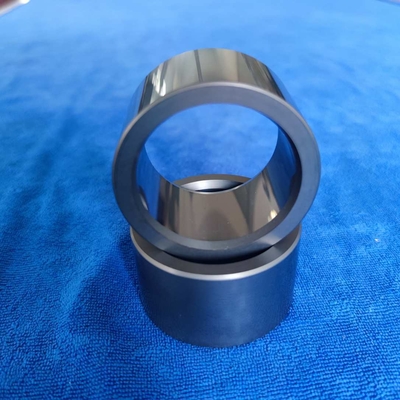

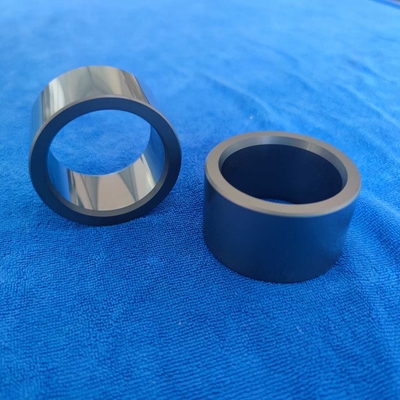

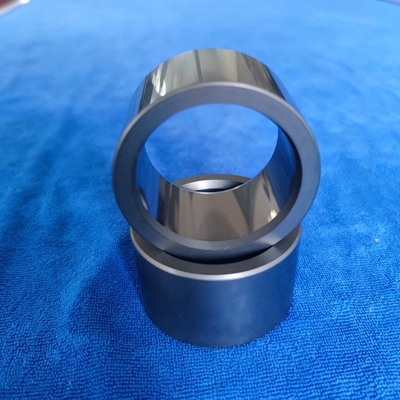

Customized SSIC Sliding Bearing Sleeve for Pumps

| Lieu d'origine | Chine |

|---|---|

| Nom de marque | CSQ |

| Certification | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Numéro de modèle | Produits personnalisés |

| Quantité de commande min | 20-50 PCs |

| Prix | negotiable |

| Détails d'emballage | Boîte en mousse + carton |

| Délai de livraison | 20-45 jours de travail |

| Conditions de paiement | t/t |

| Capacité d'approvisionnement | 2000 pièces par mois |

Contactez-moi pour des aperçus gratuits et des bons.

Whatsapp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

x| name | Palier manchon coulissant en céramique adapté aux besoins du client | Catégorie | roulements coulissants en céramique |

|---|---|---|---|

| Matériel | Carbure de silicium sintré sans pression/Zirconia | Taille | Personnalisé, selon les dessins |

| Application du projet | Pompes | Paquet | Boîte en mousse + carton |

| Qualité | Haute précision, longue durée de vie, série OEM | Spécification | Taille standard et personnalisée |

| Mettre en évidence | Customized SSIC sliding bearing sleeve,Ceramic sliding bearing for pumps,SSIC pump bearing with warranty |

||

| Attribute | Value |

|---|---|

| Name | Customized ceramic sliding sleeve bearing |

| Category | Ceramic sliding bearing |

| Material | Pressureless sintered silicon carbide/Zirconia |

| Size | Customized, according to the drawings |

| Application | Pumps |

| Package | Foam + carton box |

| Quality | High precision, Long life, OEM service |

| Specification | Standard size and customized |

Customized Silicon Carbide Sliding Bearing Sleeve

Ceramic sliding bearings are precision-engineered from high-performance materials like silicon nitride (Si3N4), silicon carbide (SiC), and zirconia (ZrO2), offering superior durability and reliability compared to traditional steel bearings. Designed for industrial, automotive, and aerospace applications, these bearings excel in corrosive, high-temperature, and high-wear environments.

- Extreme Corrosion Resistance - Withstands harsh chemicals, acids, and marine environments, ideal for chemical processing, pumps, and offshore equipment.

- Ultra-Low Friction & Wear - Smoother, harder ceramic surfaces minimize friction, reducing energy loss and extending bearing lifespan by 5-10X over metal alternatives.

- High-Temperature Stability - Operates reliably up to 1,400°C, perfect for turbines, engines, and industrial furnaces.

- Lightweight & Non-Magnetic - Reduces rotational inertia and eliminates magnetic interference, critical for aerospace and medical devices.

Ceramic bearings can be widely used in aviation, aerospace, navigation, petroleum, chemical, automotive, electronic equipment, metallurgy, electric power, textile, pump, medical instruments, scientific research and national defense and other fields, is the application of new materials of high-tech products.

| Max Temperature | up to 1650℃ |

| Density | 3.15-3.18 g/cm³ |

| Thermal Expansion | 4.0 (10-6/℃) |

| Thermal Conductivity | 120 W/m°K |

| Hardness | 2800 HV5 |

| Elastic Modulus | 410GPa |

| Chemical Stability | Superior resistance to acid and alkali corrosion (including hydrofluoric acid) |

- Ceramic bearings can be used for higher temperatures: ceramic materials can stably maintain their mechanical properties at high temperature.

- More suitable for temperature changes: thermal expansion coefficient is smaller than steel, allowing use in wider temperature fluctuations.

- Better anti-bite and anti-stuck performance: reduces thermal deformation to improve anti-bite ability.

- Can work without oil: self-lubricating characteristics allow use in high vacuum and inconvenient lubrication occasions.

- Resistant to acid, alkali and salt corrosion: suitable for chemical corrosion environments.

- Electrical insulation and no static electricity: ceramics are non-conductive without static electricity.

- Can be used in magnetic environments: ceramic is non-magnetic, preventing abrasive particles from adhering to channels.

We have three factories in China to meet different customer needs, equipped with advanced pressing, sintering and processing machines. Our company possesses eleven invention patents for utility models and has a professional team of dozens of members to provide high-quality customized bearing products.

Since 1982, we have accumulated over 40 years of experience in ceramic bearing material research and development, processing techniques, and equipment improvement. We have become a leading enterprise in China's domestic market for ceramic bearing and ceramic material products.

We have ample production experience with both external and internal gear pump sliding bearings in silicon carbide material, having supplied SSiC sliding bearings to Germany Witte for many years.

- Free sample bearings available

- ISO Standard compliant

- In-stock bearings ready for shipment

- Small order quantities accepted

- OEM bearing service

- Customized bearings from customer drawings or samples

- Competitive factory pricing

A: We are a factory in Beijing, China with over 40 years of experience producing ceramic bearings, having established cooperative relations with many domestic and foreign companies.

A: We produce samples before mass production, strictly follow customer requirements, conduct precise inspections, and use double packaging (foam + carton) to ensure product quality.

A: Ceramic deep groove ball bearings, angular contact ball bearings, hybrid ceramic ball bearings, linear bearings, and various ceramic balls.

A: As an industry and trade integrated company with three factories and modern equipment, we can provide better delivery dates and product quality.

A: We offer high quality products, fully customized services according to user needs, and can provide samples for confirmation.

We cooperate with raw material suppliers to ensure product quality and stable pricing. When necessary, we can produce raw materials ourselves. We adhere to customer demand as our guidance, striving to provide quality products and after-sales service, creating value for customers as their partner. Welcome to discuss cooperation!