Tous les produits

-

Roulements à billes en céramique

-

608 incidences en céramique

-

Incidences en céramique hybrides

-

Incidence de carbure de silicium

-

Incidence de glissement en céramique

-

Roulements à rouleaux en céramique

-

Palier de butée en céramique

-

Céramique structurelle avancée

-

Boule de nitrure de silicium

-

Boule de carbure de silicium

-

Boule en céramique de zircone

-

Roulements à billes de carbure de silicium

-

Roulement à billes de nitrure de silicium

-

Incidence en céramique de zircone

-

Étanchéité mécanique

-

RobertaLeurs incidences en céramique sont de haute précision, bons qualité et peu coûteux. Nous avons la coopération depuis de nombreuses années.

RobertaLeurs incidences en céramique sont de haute précision, bons qualité et peu coûteux. Nous avons la coopération depuis de nombreuses années. -

Olga WeinbergCette société est notre fiable et le fournisseur professionnel des incidences en céramique depuis de nombreuses années, leurs incidences en céramique, qui sont utilisées dans notre pompe sont bon de la qualité.

Olga WeinbergCette société est notre fiable et le fournisseur professionnel des incidences en céramique depuis de nombreuses années, leurs incidences en céramique, qui sont utilisées dans notre pompe sont bon de la qualité.

Personne à contacter :

Cooper wang

Numéro de téléphone :

86 15801087509

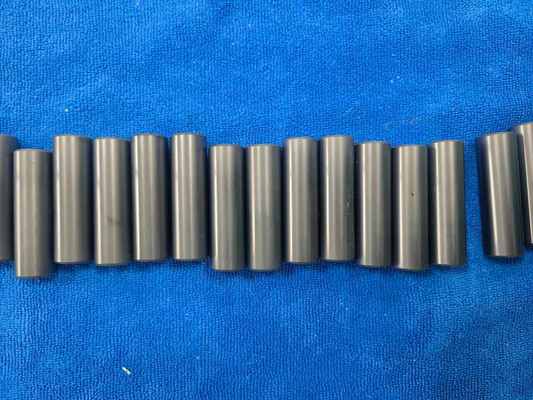

SSIC Shaft with High Temperature and Corrosion Resistance

| Lieu d'origine | CHINE |

|---|---|

| Nom de marque | CSQ |

| Certification | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Numéro de modèle | Personnalisé |

| Quantité de commande min | 20-50 PCS |

| Prix | negotiable |

| Détails d'emballage | Boîte en mousse + cartom |

| Délai de livraison | 20-45 jours de travail |

| Conditions de paiement | T / t, t / t |

| Capacité d'approvisionnement | 2000 PC par mois |

Contactez-moi pour des aperçus gratuits et des bons.

Whatsapp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

xDétails sur le produit

| Nom | Axe en céramique | Catégorie | Céramique structurelle avancée |

|---|---|---|---|

| Matériel | Céramique SSIC SI3N4 AL2O3 ZRO2 | Précision | Personnalisé, selon les dessins |

| Taille | Personnalisé | Pacage | Boîte en mousse + cartom |

| Mettre en évidence | Customized Precision SSIC Shaft,Food Machinery Ceramic Shaft,Pharmaceutical Industry Silicon Carbide Shaft |

||

Description de produit

SSIC Shaft High Temperature Corrosion Resistance For Food Machinery Pharmaceutical Industry

Customized Ceramic Shaft Of Silicon Carbide With High Precision

Our silicon carbide shaft is manufactured from highly purified, sub-micron silicon carbide material through air pressure sintering. This process results in exceptional properties including high hardness (Hv2800), superior wear resistance, resistance to strong acids, alkalis, and salt corrosion, along with excellent high temperature performance.

Key Features

Key properties of pressureless sintered silicon carbide:

- Maximum temperature resistance up to 1650℃

- Low density: 3.15-3.18 g/cm³

- Exceptional mechanical strength

- Low thermal expansion: 4.0 (10-6/℃)

- High thermal conductivity: 120 W/m°K

- Extreme hardness: 2800 HV5

- High elastic modulus: 410GPa

- Superior chemical stability with resistance to acid and alkali corrosion (including hydrofluoric acid)

Technical Specifications

| Parameter | Value |

|---|---|

| Density | 3.10-3.13 g/cm³ |

| Flexural Strength | 550 MPa |

| Thermal Conductivity | 120 W/m*K |

| Max Operating Temp | 1650°C |

Ceramic vs Steel Material Comparison

- Higher temperature capability: Ceramic maintains mechanical properties at elevated temperatures

- Better thermal stability: Smaller thermal expansion coefficient reduces clearance variation

- Superior anti-bite performance: Reduced thermal deformation improves resistance to seizing

- Self-lubricating: Operates without oil lubrication in vacuum or difficult environments

- Chemical resistance: Withstands acid, alkali, and salt corrosion

- Electrical insulation: Non-conductive with no static electricity generation

- Non-magnetic: Ideal for magnetic environments with reduced abrasive wear

Why Choose Our Products

Professional Team: With the brand names ZXSQ and CSQ, we hold eleven invention patents and maintain a professional team dedicated to providing customized bearing solutions. Since 1982, we've accumulated over 40 years of expertise in ceramic bearing material research and development.

Manufacturing Strength: Our fully automated production line has an annual capacity of 3 million sets of P5 and P4 precision bearings. Equipped with industry-leading firing technology including a Swedish ABB hot isostatic sintering furnace (HIP), we achieve firing temperatures exceeding 2000℃.

Frequently Asked Questions

Who are we?

We are a Beijing-based factory with over 40 years of experience in ceramic bearing production, maintaining cooperative relationships with domestic and international companies.

How do we guarantee quality?

We implement strict quality control including pre-production samples, precise inspections, and double-layer packaging (foam + carton) to ensure product integrity.

What products do we offer?

Our product range includes ceramic deep groove ball bearings, angular contact bearings, hybrid bearings, linear bearings, and various ceramic balls.

Why choose us over competitors?

As an integrated manufacturer with three factories, we combine advanced production technology with quality inspection capabilities to deliver superior products with reliable lead times.

What services do we provide?

We offer high-quality products with full customization options, including sample provision for customer verification.

Contact Us

We specialize in bearing research, production, and sales, committed to providing quality products and technical services. Using premium materials and meticulous craftsmanship, we create value through customer-focused solutions and reliable after-sales support. Contact us to discuss your requirements and potential cooperation.

Évaluations et avis

produits recommandés

Notation globale

Capture d'écran de notation

Voici la répartition de toutes les notesToutes les critiques